Die Cutting Solutions for Electric Vehicle Batteries

The recent growth in demand for electric vehicles (EV) and fuel cell technologies necessitates high-volume production of intricate battery and fuel cell components that prioritize precision and efficiency. Hyperion Materials & Technologies’ rotary die cutting solutions empower manufacturers to achieve cost-effective and scalable manufacturing to meet the increasing demand for clean energy vehicles.

Rotary Die Cutters for Electric Vehicle Batteries

Rotary die cutting offers a powerful solution for shaping a wide range of materials used in EV battery and fuel cell production. The precise, high-speed cutting capabilities of Hyperion’s rotary cutters ensure consistent part geometries while minimizing material waste and defects that can negatively impact battery performance. With the ability to seamlessly integrate into automated production lines, rotary die cutters can reduce the reliance on manual labor and improve overall throughput.

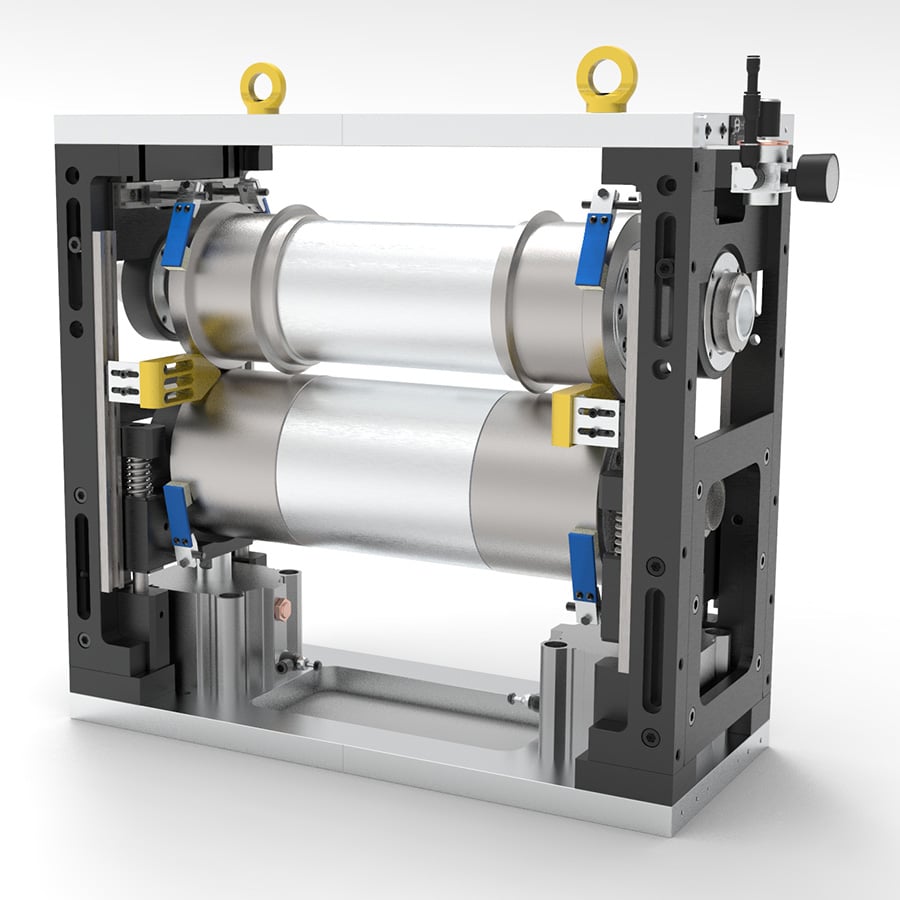

Hyperion Slitting Unit for Electrode Foil.

Download the tech note to learn more about how rotary die cutting can help manufacturers achieve scalable, precision production of EV battery and fuel cell components.

Rotary Cutters