Aerospace Tooling Solutions

Manufacturing aerospace components dictates materials that meet some of the strictest requirements for corrosion resistance, toughness, workability, and durability.

The strength and wear resistance of cemented carbide make it the best choice for tooling to produce aerospace components, as other materials cannot withstand the tough environmental conditions. The properties of cemented carbide allow it to adapt to conditions as equipment performance intensifies.

Hyperion provides hard and super-hard materials as well engineering expertise that help you machine and produce aerospace components, including:

- Our Application Specific grades of carbide rods and end mill blanks are ideal for the challenging machining of superalloys.

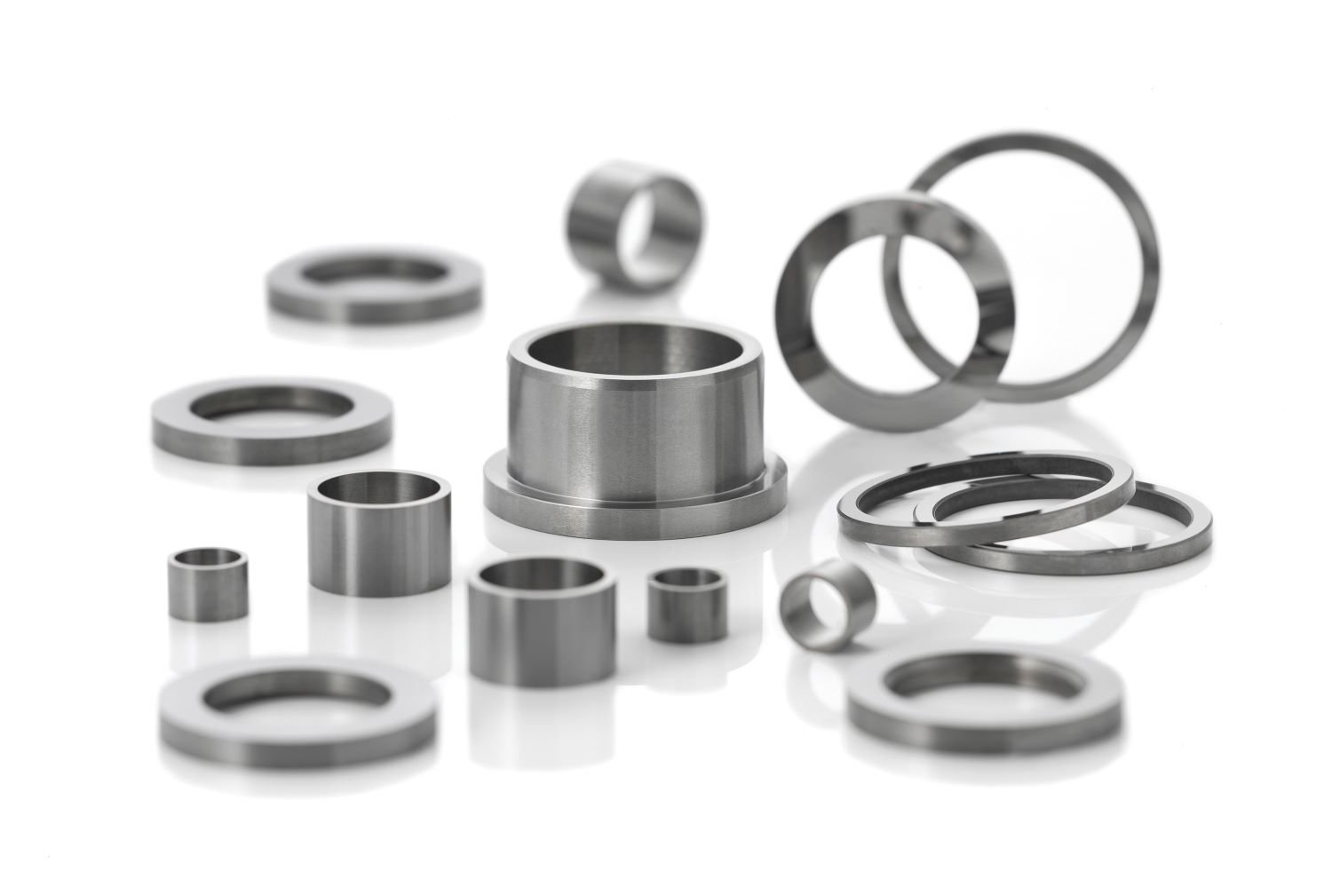

- Wear parts used in various applications in the aerospace industry, including bearings, vane pump body, shafts, and pistons.

- Diamond coatings applied to wear parts to promote longer life. This coating can be applied to any shape regardless of intricacy and without line of sight.

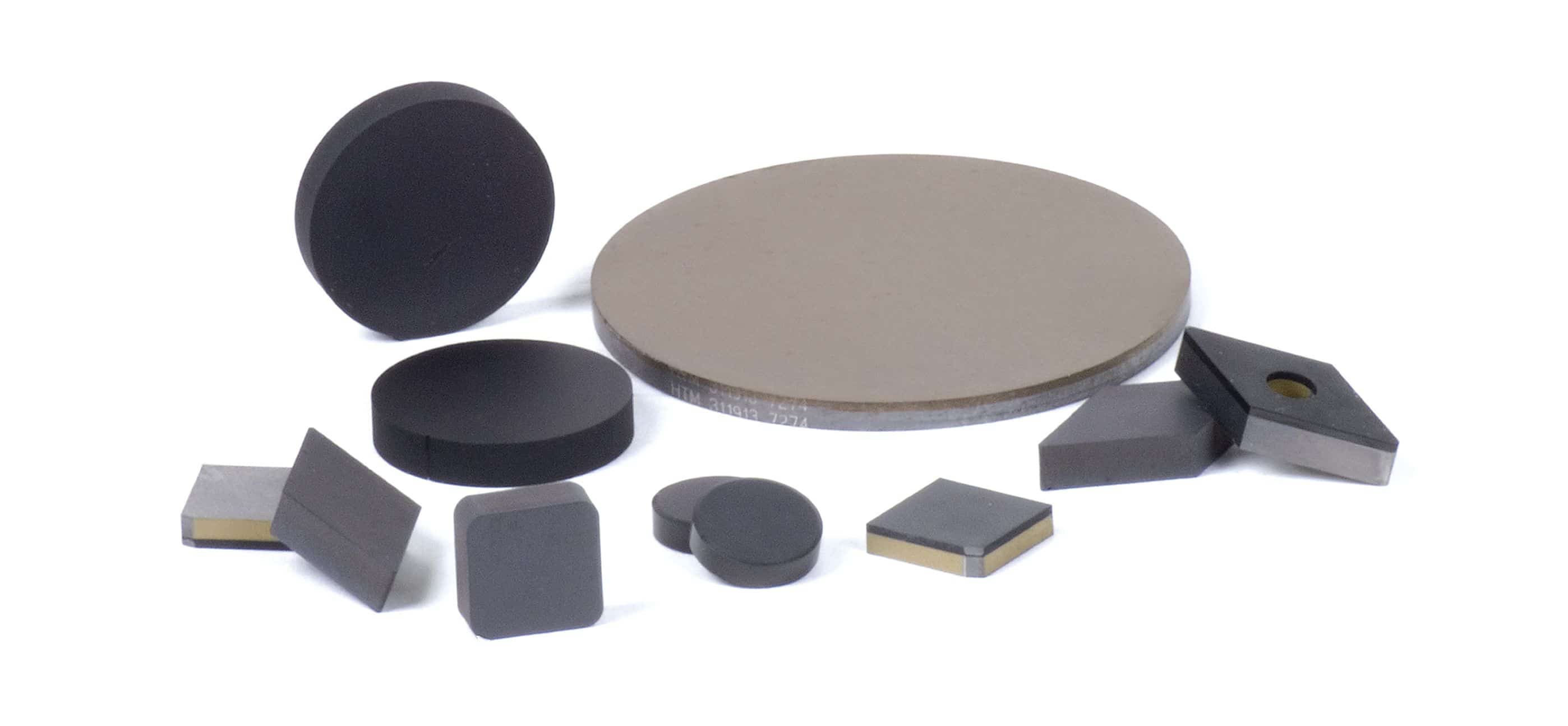

- A complete line of PCD and PCBN used to cut, machine, and finish ferrous materials, aluminum, and superalloys.

Tooling Solutions that serve the Aerospace Industry:

|

Cemented carbide rods, with and without coolant channels, for drills and end mills |

Cubic boron nitride (CBN) abrasives for grinding wheels and dicing blades |

|

Advanced protection through our proprietary diamond composite coatings |

PCD/PCBN blanks and cut shapes for inserts and round tools in metal cutting |

|

Cemented carbide custom parts that withstand high pressures, high temperatures, and corrosion |

Learn more about cemented tungsten carbide: