Hyperion Diamond Powder

Type: Micron and sub-micron synthetic diamond powder

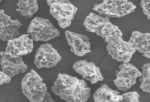

Description: Hyperion Diamond powder is a patented unique diamond with a modified surface containing many fine micro-points that drastically reduce the surface roughness of the workpiece.

Hyperion Diamond Powder Size Chart

With the booming electronics industry and the increased demand for silicon carbide wafers, efficiency and throughput with manufacturing is paramount. Hyperion Diamond powder continues to expand beyond slurries to grinding applications with very fine size crystals. With its high material removal rate and excellent surface finish capabilities, Hyperion Diamond powder helps manufacturers quickly produce more epi-ready wafers with an extremely smooth surface, free from scratches, pits, or defects, that exhibit remarkable longevity.

Hyperion Materials & Technologies provides a complete line of Hyperion Diamond solutions available in micron and submicron sizes, ranging from 0.25µ to 100µ. The powder can also be formed in a slurry or suspension to optimize the performance for specific operating conditions and workpieces.

| Hyperion Diamond Powder Sizes | ||

|---|---|---|

| Diamond Sizes | Container Sizes | |

| 0-0.5* | 5-10 | 500 ml |

| 0-1* | 6-12 | |

| 0.5-1* | 8-16 | |

| 0-2 | 10-20 | 1 Liter |

| 1-3 | 12-25 | |

| 1-3 | 15-25 | |

| 2-3 | 20-30 | 1 Gallon |

| 2-4 | 20-40 | |

| 3-5 | 30-40 | |

| 3-6 | 40-50 | 50 Gallon |

| 4-6 | 50-70 | |

| 4-8 | 60-80 | |

Product Details

Hyperion™ Diamond powder is a patented superabrasive comprised of synthetic diamond crystals with a unique etched surface containing more cutting points than a typical monocrystalline micron or polycrystalline micron diamond. The unique features of this diamond are most often utilized in precision applications such as semiconductors, sapphire, metallography, and fine finishing where efficient material removal rates and reduced surface roughness are important.

With an increased number of micro-points, Hyperion Diamond powder creates a unique surface characteristic that also helps the crystal to retain its size and maintain effectiveness throughout the machining process. This is unlike alternative diamond options with fewer cutting points that are more susceptible to crushing and becoming smaller with use.

Hyperion Diamond powder is readily available and offers toolmakers a superabrasive designed for precision applications of non-ferrous materials with excellent surface roughness resistance.

For additional convenience, Hyperion also offers a global network of sales, customer service, and technical support experts to help guide customers throughout the process. Within customer support, Hyperion provides testing, fabrication, and application development support through its R&D center in Worthington, Ohio.

Hyperion also offers metal bond and resin bond micron diamond products designed for exceptional performance in slicing and dicing precise applications.