Ultra Premium Micron Diamond Powder

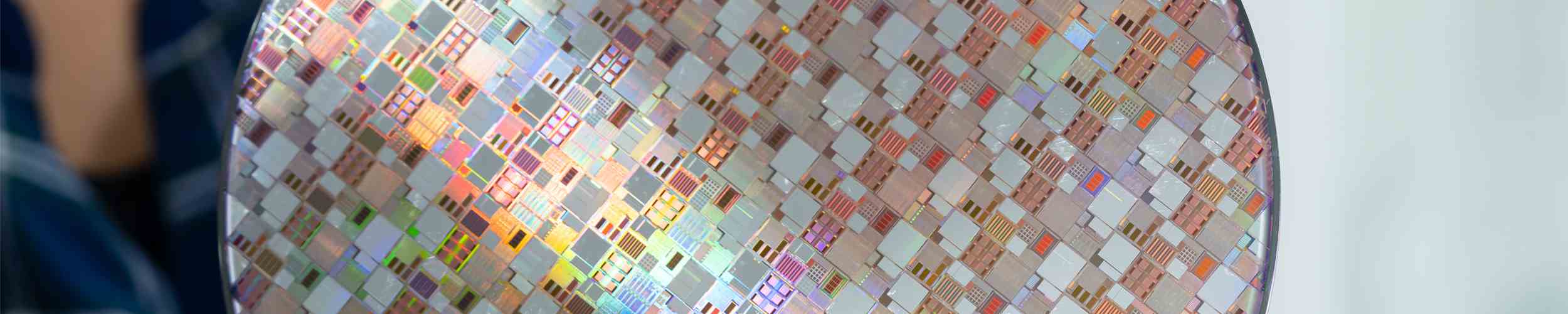

Ultra premium micron diamond powders (UPM) are high-quality synthetic diamond powders designed to minimize costly chipping and scratching issues in precision processes, such as processing silicon and silicon carbide semiconductor wafers for chip making. UPM diamond powders exhibit the industry's most tightly controlled size, shape, and surface properties, resulting in superior reproducibility.

Derived from synthesized monocrystalline diamonds, these ultra-premium products are grown under conditions that create uniform crystals that resist fracturing and have excellent impact resistance. Hyperion's advanced manufacturing process has continuously improved to deliver a product with unparalleled performance in detecting and removing oversized particles, which is a critical feature for customers with precise tooling applications in the semiconductor markets.

Oversized particles can be extremely difficult to detect with traditional particle size detection techniques because they exist in such low amounts. It's essential to find oversized particles because they can cause chipping, scratching, and imperfections in the wafer, which can lead to a total loss of the wafer and result in the loss of hundreds of chips. Hyperion innovatively developed the UPM grade to help detect these oversized particles in ppb concentrations and efficiently remove them, ensuring a high-quality end product and significant cost avoidance.

Available in standard diamond size fractions and customizable to meet specific surface cleanliness requirements, UPM powders allow semiconductor manufacturers to use thinner dicing blades to cut wafers. This results in less chipping and material loss, producing a higher yield of electrical components from each wafer. Back-grinding wheels with UPM result in wafers with fewer scratches and superior surface finishes.

Product Groups

Hyperion Code: UPM

Description: Synthetic ultra premium micron diamond powder is designed for processes where a precise size range and consistency are key. Designed for exceptional performance when back-grinding, dicing, and other precision machining of silicon and semiconductor wafers.

Hyperion Code: UPM

Description: Synthetic ultra premium micron diamond powder is designed for processes where a precise size range and consistency are key. Designed for exceptional performance when back-grinding, dicing, and other precision machining of silicon and semiconductor wafers.

Ultra Premium Micron Benefits

Due to the industry's most tightly controlled size, shape, and surface properties, Hyperion's UPM diamond powders exhibit several benefits for precision machining applications. The ultra-precise particle size distribution produces superior reproducibility, minimizing chipping and material loss and providing higher production yields.

Ultra Premium Micron Applications

UPM is designed for precision machining applications due to its low levels of oversized particles, essential for achieving the required precision, surface finish, and dimensional accuracy. The uniformity and sharpness of the diamond parts allow for controlled material removal and minimal subsurface damage, resulting in high-quality precision machined parts for semiconductors, microelectronics, optics, photonics, medical devices, aerospace components, and mold and die making.

Frequently Asked Questions about Micron Diamond Powders

Ultra Premium Micron Diamond Powder (UPM) are high-quality synthetic diamond powders designed for processes where a precise size range and consistency are critical. Specifically produced for exceptional performance in back-grinding, dicing, and other precision machining of silicon and semiconductor wafers, UPM powder resolves costly chipping and scratching issues in SiC wafer processing for chip making.

Ultra Premium Micron Diamond Powder exhibits several benefits for precision machining applications. UPM diamonds contain the industry's most tightly controlled size, shape, and surface properties. Derived from synthesized monocrystalline diamonds, these ultra-premium products are grown under conditions that create tough, uniform crystals that resist fracturing and have exceptional impact resistance. The ultra-precise particle size distribution produces superior reproducibility, minimizing chipping and material loss and providing higher production yields.

Ultra Premium Micron Diamond powders are availalbe in standard diamond size fractions and can be customized to meet specific customer requirements for both size and surface cleanliness.

Ultra Premium Micron Diamond Powder is designed for precision machining applications due to its low levels of oversized particles, essential for achieving the required precision, surface finish, and dimensional accuracy. The uniformity and sharpness of the diamond parts allow for controlled material removal and minimal subsurface damage, resulting in high-quality precision machined parts for semiconductors, microelectronics, optics, photonics, medical devices, aerospace components, and mold and die making.

Ultra Premium Micron Diamond Powders are unique because they have the industry's lowest level of oversized particles thanks to the UPM process developed at Hyperion to detect these oversized particles in ppb concentrations and remove them. Oversized particles can cause chipping, scratching, and imperfections in wafers' surface quality. UPM can help customers perfect their precise tooling and applications in the semiconductor and compound semiconductor markets by containing limited oversized particles.