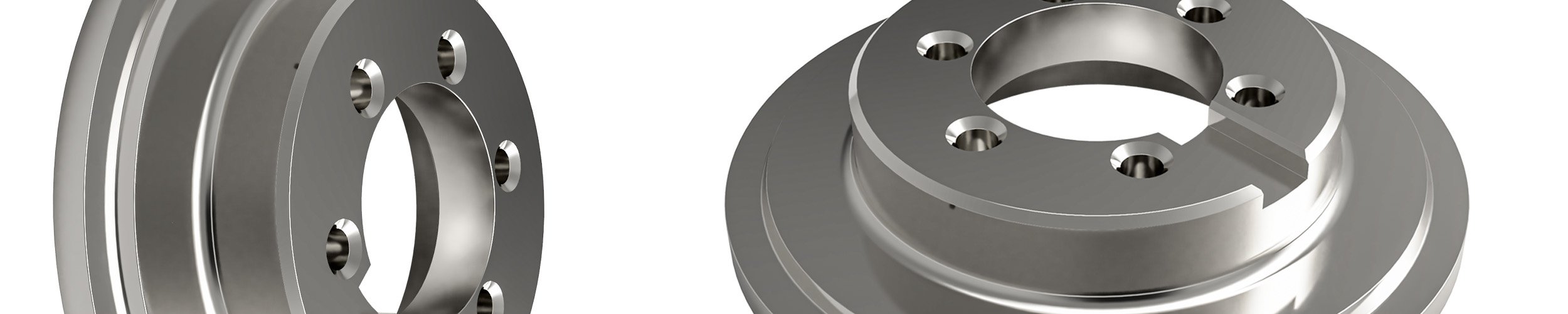

Skivit™ Power Skiving Blanks

Skivit power skiving blanks are cemented carbide blanks customized to the needs of toolmakers who manufacture power skiving tooling. Toolmakers use them to form efficient tools for machining operations, which gear manufacturers then use to produce high-precision gears, splines, and other complex and precise tooth profiles. Power skiving combines hobbing and shaping operations to produce high-precision internal and external gears efficiently.

Automakers, gear manufacturers, and users demand higher machining precision in their gears to achieve lower fuel consumption, reduced noise, and other efficiency gains. Generating more efficient gear machining is also key to compensating for labor shortages and increasing cost competitiveness.

Skivit power skiving blanks offer an accurate and flexible option for toolmakers who require efficient power skiving tools for gear manufacturing. They are manufactured with industry-leading carbide grades for advanced metal-cutting operations. Their exceptional dimensional control, including tight tolerances and superior surface finishes, enables toolmakers to optimize their manufacturing methods.

Skivit power skiving blanks are sintered to be as close to your finished tool as possible. Near-net-shape geometries with value-added features, like angular faces, slots, and grind stock, reduce machining time and generate significantly faster tooling production times. This helps toolmakers compensate for labor shortages and increase cost competitiveness.

Skivit Power Skiving Blanks Applications

Advances in machining centers have paved the way to a more productive process for producing internal and external gears called power skiving. Skivit power skiving blanks offer toolmakers a specialized and highly efficient method of finishing power skiving tools. These tools are then utilized to manufacture highly precision gears and splines for various industries, including automotive aerospace, robotics, power generation, and general machinery.

Power skiving, a combination of hobbing and shaping operations, is a highly versatile machining method that does not require a significant investment compared to expensive hobbing machines. It offers improved quality at a lower cost and is 4 to 10 times more productive than hobbing or shaping. Power skiving methods increase the productivity in the gear manufacturing process by providing precise stability, complex tooth profiles, and the ability to be retrofitted to any CNC machine.

FAQ about Skivit™ Power Skiving Blanks

Skivit power skiving blanks are cemented tungsten carbide blanks manufactured to the desired customer geometry by pressing cemented carbide powder to the shape and sintering at high temperature and pressure to achieve the desired strength and hardness. Toolmakers form the blanks into ready-to-use tools, which gear manufacturers implement to produce high-precision gears that are accurate and quiet during operation. Power skiving combines hobbing and shaping operations to efficiently produce high-precision internal and external gears, splines, and other complex and precise tooth profiles.

Skivit power skiving blanks are processed into tools that can be easily installed on a traditional CNC machine to manufacture gears. This enables the production of highly precise gears, splines, and complex tooth profile components. While suitable for both external and internal gears, they excel in internal gear machining.

Skivit power skiving blanks offer several advantages to tool manufacturers. Made from industry-leading carbide grades for advanced and high-productivity metal-cutting operations, they boast exceptional dimensional control with tight tolerances and superior finishes, allowing for optimized tool production. Skivit blanks are also developed in near-net shapes with value-added features like angles, slots, and grind stock to significantly reduce machining time and boost production speed, helping toolmakers overcome labor shortages and remain cost-competitive. Finally, Hyperion's secure supply chain, spanning raw materials to finished blanks across the Americas, Asia, and Europe, allows toolmakers to streamline operations and rely on local support for developing intricate and innovative tools to stand out from the competition.

Skivit power skiving blanks can be formed into tools that produce a wide range of tooth profiles, including spur gears, helical gears, internal gears, and complex forms like serrations or asymmetric teeth.

Hyperion offers Skivit power skiving blanks in a wide range of sizes sintered to near-net shape. Combined with industry-leading carbide grades, H10F and H6F, Skivit blanks provide value-added grinding options like top face-bottom face, periphery chamfer, bottom chamfer, angles, keyways, and bolt holes. Additional sizes and shank style power skiving tools are also available on request.

As a partner supplier, Hyperion provides complex geometry designs, near-net shape offerings, blanks, and semifinished parts. A partner supplier will never provide a completed finished power skiving tool that competes with you and helps differentiate your products with specialized materials, features, and services while reducing your processing requirements. Another important consideration for a partner supplier is they can streamline your operations. At Hyperion, you can rely on local suport in developing complex, innovative, and unique power skiving blanks to compete against commodity-type competition.

Skivit power skiving blanks are formed by toolmakers into finished power skiving tools commonly used to manufacture gear components in automotive, aerospace, power generation, robotics, and general machinery applications. Typical applications that utilize power skiving tools are automotive transmissions, such as synchronizer rings, planetary gears, and differential gears. Along with automotive parts, skivit power skiving blanks can be used for power tools, such as angle grinders and drills, landing gear systems, aircraft engines, surgical instruments, and robotic systems.

Skivit power skiving blanks contribute to longer tool life through several key factors. Firstly, they're manufactured from a premium portfolio of proven, worldwide-known cemented carbide grades, ensuring reliable performance. This empowers toolmakers to develop tools that achieve faster certification and simplify integration into existing applications due to the predictable adhesion of coatings. Furthermore, the diverse range of grades reduces the need for extensive testing, allowing for a better fit for specific customer needs. Utilizing these premium grades streamlines operations by minimizing incoming inspections, reducing quality claims, lowering stock requirements, and consequently leading to lower overall operating costs.

There are several factors to consider when selecting Skivit power skiving blanks as the best material for your solution. Skivit blanks are produced with proven, reliable cemented carbide grades, allowing toolmakers to create tooling with faster certification, streamlining operations by minimizing incoming inspections, lowering quality claims, reducing stock needs, and, ultimately, lowering operating costs. They also provide exceptional, consistent quality processes and superior materials, allowing toolmakers to claim brand protection and value confidently. The reliable performance of Skivit blanks helps reduce the risk of rejections, disruptions, and rework. Additionally, Skivit blanks are provided in complex geometry designs and near-net-shape offerings to allow toolmakers to develop finished tools effectively and efficiently, reducing their processing requirements.