BZN™ V-Series PCBN

Type: Full Round or Cut Tips

Number of Grades: 3

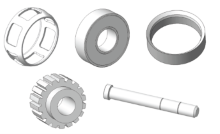

Description: PCBN pre-form grades machined in turning, milling, and reaming tools to improve tool life and production. This provides versatility in three key aspects: workpiece composition, application demands, and component type.

What is BZN™ V-Series about?

Hyperion Materials & Technologies manufactures PCBN versatile grades for machining hardened steels, called V-Series. As it becomes more challenging to machine hardened steels with changing and evolving alloy compositions, machine tools, and fabrication features, Hyperion has developed a product line of innovative grades to help toolmakers and end users stock multiple PCBN products across a wide range of applications.

BZN™ V-Series allows customers to maximize their flexibility in machining hardened ferrous materials by providing versatility in three key aspects:

- Workpiece composition – case hardened, bearing steels, powder metal alloys, alloy steels, and tool steels

- Application demands – turning, milling, and reaming

- Component type – Bearings, shafts, gears, CV joint components, valve seat machining, and die/mold components

In addition to versatility in applications, the BZN V-Series provides customers with enhanced wear and fracture resistance, performance repeatability, and uniform layer thickness.

Cutting speed comparisons among BZN products

BZN V-Series Solutions

BZN V-Series offers three grades recommended for machining turning, milling, and reaming tools. Discover the portfolio and learn which option best solves your needs.

BZN V20 Compacts

Applications: hardened steel (wet and dry), valve seat materials, and cold work tool steels.

BZN V25 Compacts

Applications: medium interrupted turning, powder metal machining, and CV joint applications.

BZN V35 Compacts

BZN V35 compacts is a grade that consists of titanium nitride binder with 70 to 75% cBN content. The grade is designed for applications requiring superior edge toughness, such as medium to heavy interrupted cutting of hardened steels. It can also provide excellent chipping resistance in the continuous cutting of high alloy powder metal applications. Typical cutting speeds are 80 to 150 m/min with 0.05 to 0.40 mm depth of cut.

Applications: heavy interrupted turning, valve seat machining, and CV joint applications.

Hyperion has also introduced the BZN VS-Series as a complement to the BZN V-Series.