Rotary Die Cutter Extensions

Through a deep understanding of rotary die cutter and converting line applications, Hyperion Materials & Technologies has developed a range of rotary die cutter extensions that can integrate seamlessly into existing processing lines. Hyperion’s line of rotary cutter extensions for rotative cut, straight cut, and slitting applications are made of high-quality materials to offer customers solutions to improve cutting performance, flexibility and efficiency of the line to optimize productivity while maximizing savings over the life of the tooling.

Product Groups

Type: IQUT

Dimensions: as per drawing/requested

Description: Embracing the trend of Industry 4.0, we have developed an intelligent rotary cutting solution able to measure and monitor the parameters that have an influence on the cutting performance.

Type: HTC

Dimensions: as per drawing/requested

Description: Patented rotary cutter extension based on HTC technology is specifically suitable for improving cutting stability and reliability in processes running at high speeds or in challenging cutting conditions. It includes a dampening device able to stabilize the cut and thus enhance rotary cutting performance.

Type: Helicut

Dimensions: as per drawing/requested

Description: Patented Helicut rotary cutting technology is suitable for cutting profiles that are oriented in the cross direction compared to the material flow, thus requiring high cutting forces and generating vibrations. With Helicut, the cutting process becomes smoother and performance is greatly enhanced.

Type: A-Flex

Dimensions: as per drawing/requested

Description: A-Flex rotary cutting technology allows customers to quickly replace the anvil without disassembling the rotary cutter unit from the line. This solution reduces downtime and optimizes the need for spare parts, thus generating savings.

Type: IQUT

Dimensions: as per drawing/requested

Description: Embracing the trend of Industry 4.0, we have developed an intelligent rotary cutting solution able to measure and monitor the parameters that have an influence on the cutting performance.

Type: HTC

Dimensions: as per drawing/requested

Description: Patented rotary cutter extension based on HTC technology is specifically suitable for improving cutting stability and reliability in processes running at high speeds or in challenging cutting conditions. It includes a dampening device able to stabilize the cut and thus enhance rotary cutting performance.

Type: Helicut

Dimensions: as per drawing/requested

Description: Patented Helicut rotary cutting technology is suitable for cutting profiles that are oriented in the cross direction compared to the material flow, thus requiring high cutting forces and generating vibrations. With Helicut, the cutting process becomes smoother and performance is greatly enhanced.

Type: A-Flex

Dimensions: as per drawing/requested

Description: A-Flex rotary cutting technology allows customers to quickly replace the anvil without disassembling the rotary cutter unit from the line. This solution reduces downtime and optimizes the need for spare parts, thus generating savings.

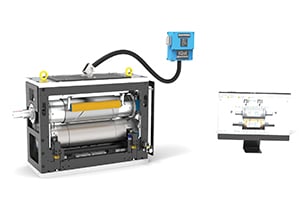

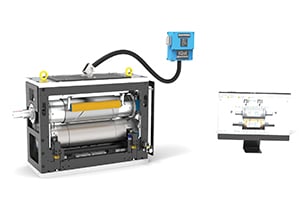

IQUT

Hyperion’s intelligent rotary cutting solution extends the capabilities of cutting units on the converting line with sensors and communication tools to help customers collect critical working data and improve process controls.

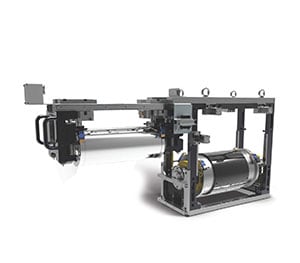

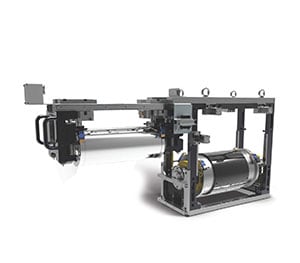

Helicut

Helicut is designed for cutting profiles that are oriented across the material flow and provides a smooth cut with no vibrations. Patented Helicut technology offers reduced vibrations and smooth cuts ensuring high-efficiency cutting that reduces machine downtimes for maintenance and the need for spare parts.

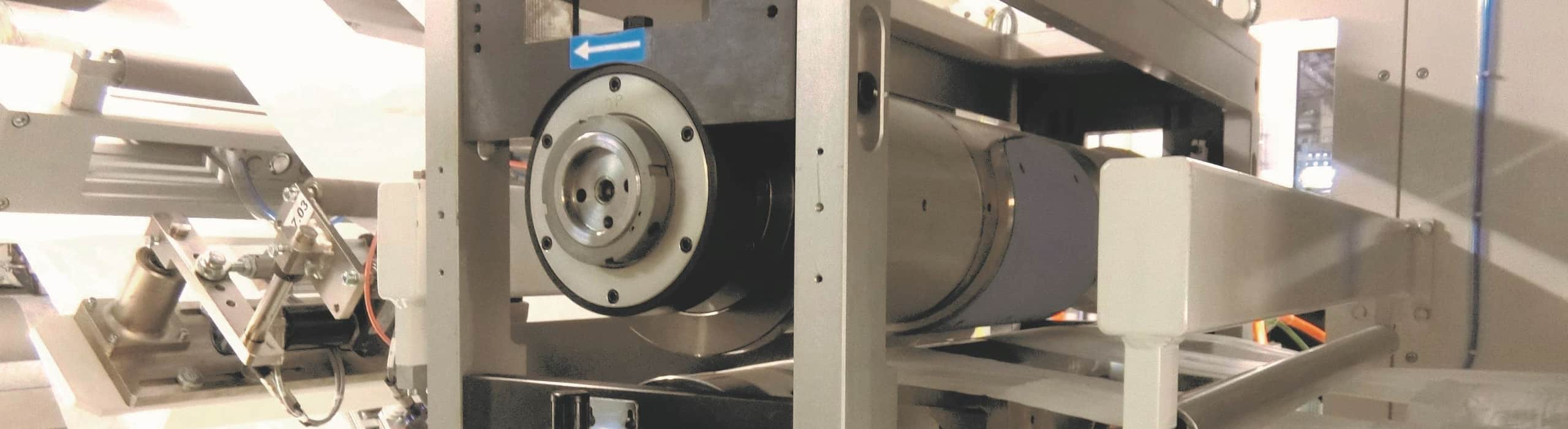

HTC – High Technology

The HTC extension by Hyperion offers a vibration damping system to protect the anvil and cutting edge that can lengthen tool lifetimes by up to 50 percent. HTC also features a tuned mass damper for stable cutting at high speeds and a specific vacuum system design for perfect trim and pad control.

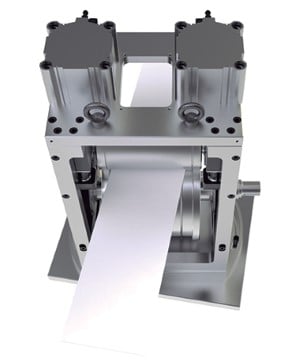

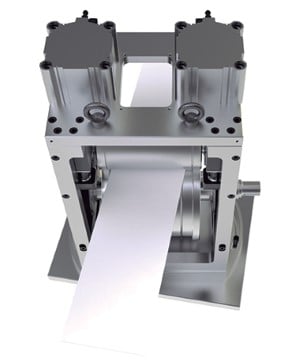

A-Flex

The A-Flex rotary cutter extension utilizes a sliding quick anvil change system to allow anvil replacement without disassembly of the rotary cutting unit to reduce downtime for maintenance and optimize productivity.

Frequently Asked Questions about Rottary Cutter Extensions

Rotary cutter extensions are technologies designed to enhance cutting solutions for the unique needs of specific applications. Hyperion’s rotary cutter extensions can be added to upgrade your cutting operations.

Hyperion manufactures rotary cutter extensions to upgrade your cutting operations, including:

- QUT to add advanced monitoring of cutting conditions from computers and other devices

- HTC to enhance the operation of high-speed cutting applications

- Helicut to optimize straight cut applications, especially those that require cuts across the flow of fabric

- A-Flex to provide a quick-change operation for switching anvils in use on a cutting solution.

Hyperion Materials & Technologies' IQUT technology bridges the gap between traditional rotary cutters and Industry 4.0. By integrating embedded and external sensors into the cutting unit, IQUT captures real-time insights into critical cutting parameterssuch as temperature, vibration, and blade wear.

Hyperion Materials & Technologies offers various rotary cutter extensions, each with specific strengths and ideal applications. The extension best suited for your application depends on various factors including material, cutting requirements, and production goals.

Contact a Hyperion product specialist for assistance selecting the rotary cutter extension best suited to your application’s unique cutting needs.

Hyperion Materials & Technologies produces its rotary cutter extensions in France, from the initial powder to the finished product. The carbide powder is shipped from Hyperion’s powder facility in Grenoble to Epinouze where it is transformed into final components used in the rotary cutter extensions.

Hyperion Materials & Technologies supports customers with the carbide recycling of used rotary cutter extensions and tooling. Hyperion, through its Carbide Recycling Program, will purchases used carbide cutting extensions and parts from customers to convert them back into usable raw materials for future production.

To learn more about recycling rotary cutter extensions, visit the Hyperion Carbide Recycling Program page, or contact a Hyperion product specialist.