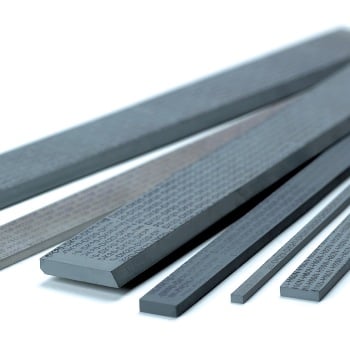

High Performance Carbide Strip Blanks

Hyperion Code: RW

Dimensions: Metric

Description: Cemented carbide strip blanks for reamers, knives, cutters, and free-forming applications, available in variable dimensions with an overall length of 310mm and in three standard profiles: rectangular (R), single chamfer (RF), or double chamfer (FF). They are designed to meet toolmakers’ specific application needs.

Advantages of High-Performance Carbide Strip Blanks

High-performance carbide strip blanks are pre-shaped bars of cemented carbide material designed to make cutting tools and wear parts for toolmakers. Available with or without chamfer and in a wide range of carbide grades, high-performance strip blanks are ideally suited for reamers, knives, cutters, and several free-forming applications.

Manufactured in industry-leading grades, high-performance tungsten carbide strip blanks are a smart investment for toolmakers. They provide exceptional hardness, wear resistance, and durability to metal, wood, and concrete tool applications, making them a valuable material for tool fabrication.

High-performance carbide strip blanks enhance tool productivity and minimize inspections. They also provide several advantages, such as reducing quality claims, stock material, and operating costs. By ensuring consistent quality and performance, these carbide blanks prove their worth. Moreover, Hyperion’s engineering experts can provide tailored materials and designs to meet specific challenges.

Long Tool Life & Consistent Quality

Due to its exceptional carbide grade materials, high-performance tungsten carbide strip blanks ensure incredible cutting performance and wear resistance. It offers a cutting edge that stays sharper for longer, allowing the tool to perform at its best for extended periods, translating to a longer tool life and more consistent cutting material. Tungsten strip blanks contain materials that can be tailored to meet specific toolmakers’ designs to meet application-specific challenges.

Streamline Your Manufacturing Process

High-performance strip blanks are designed to make toolmakers' lives easier. These pre-shaped tool blanks reduce residual stress, generate less waste, create a stronger cutting edge, and improve processing time. With three standard profiles to choose from (rectangular, single chamfer, and double chamfer), these tungsten strip blanks save time and money during the manufacturing process while enhancing the finished tool's performance. Toolmakers can also select chamfer options to streamline their process further.

High Performance Carbide Strip Blanks Applications and Industries

The versatility of carbide strip blanks shines through their applications across various industries, including automotive, shipbuilding, woodworking, and nuclear power. These industries require tools that utilize carbide strip blanks to create unique tools and wear parts.

Reamers

High-quality carbide-grade materials provide excellent hardness, toughness, wear, and heat resistance, making them a perfect solution for developing reamers. Reamers, cutting tools used in metalworking to refine existing holes, benefit from brazed-on carbide strip blanks that enable cutting specific shapes or replacing worn-out reamer knives. The advantages of brazed-on carbide strip blanks extend to other tools as well.

Knives / Cutters

Tungsten carbide strip blanks can be cut and ground to create industrial knives and cutters. They are best suited for high-volume production and when working on very hard applications where carbide’s superior wear resistance helps the cutting edge stay sharp for longer cuts and prevents chipping that softer steels might experience.

Free forming applications

High-performance carbide strip blanks provide excellent wear resistance for cutting edges of tools used in free-forming applications to create intricate components like LED frames.

High Performance Carbide Strip Blanks Properties

Hyperion carbide strip blanks are available in three standard designs: rectangle, single chamfer (30°), and double chamfer (30° and 45°). The standard carbide grade is Hyperion’s high-performance H10F, but strip blanks are available in additional application-specific carbide grades.

Carbide Strip Blanks Sizes and Dimensions

|

Strip Blank Type |

Strip Dimensions (mm) |

Standard Cemented Carbide Grade |

|||

|---|---|---|---|---|---|

|

Length |

Width |

T** (thickness choices in steps of 1 mm) |

|||

|

Minimum |

Maximum |

||||

|

RW FF |

310 |

6 - 18 |

2.0 |

6.0 |

H10F |

|

RW FF |

310 |

20 - 40 |

3.0 |

6.0 |

H10F |

* Sequence (width and thickness) = 1.0 mm.

**Please contact your Hyperion product specialist for thicknesses outside the range shown in the table.

To review our full size availability, please consider downloading the High Performance Carbide Strip Blank Sizes and Dimensions document by clicking on the provided link.

Carbide Strip Blanks Application Grades

| Grade | Application Guide |

| H6F | H6F is suitable for general Non-Ferreous manufacturing applications like Aluminium alloys and Brass. |

| H10F | H10F is suitable for general steel manufacturing applications including non-tempered steels, stainless steel, cast iron and non-ferreous materials llike Aluminium Alloys and Brass. |

| H12F | H12F is suitable for general steel manufacturing applications like Stainless Steel, steel, Mild Steel and Hardened Steel |

| H15F | H15F is suitable for general manufacturing uses. |

For additional convenience, Hyperion also offers a global network of sales, customer service, and technical support experts to help guide customers through the entire process. Within customer support, Hyperion provides testing, fabrication, and application development support through its R&D center in Worthington, Ohio.

Hyperion also offers all-purpose strip blanks for simplified fabrication and metal cutting saw tip blanks for saw blades. Discover the cemented carbide strip blanks that best suit your machining needs.