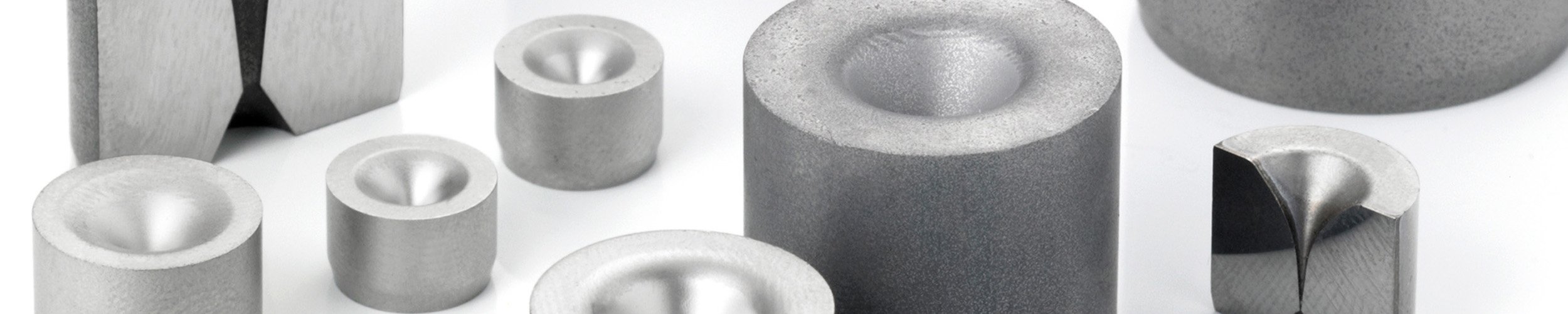

Cemented Carbide Nib Blanks

Cemented carbide nib blanks are made of tungsten carbide and a metallic binder, such as cobalt. It is commonly used in wire drawing, which reduces the diameter of a metal wire by pulling it through a series of dies with decreasing hole sizes.

Carbide nib blanks come into direct contact with the wire as it passes through the die. The nibs are designed to withstand the high pressure and wear of the wire drawing process while maintaining their shape and size over time.

Using carbide nibs in wire drawing offers several advantages over other materials, such as longer tool life, reduced downtime, and improved wire surface finish. They can also draw a wide range of metals, including steel, copper, and aluminum. Overall, cemented carbide nibs are essential for the wire drawing industry.

Product Groups

Hyperion Code: WDSNR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication to DIN 1547.

Hyperion Code: WDINR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication to ISO 1684.

Hyperion Code: WDJNR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication to JIS G3521.

Hyperion Code: WDSNR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication of drawing dies with an exit diameter between 12 and 61 mm.

Hyperion Code: WDRNR

Dimensions: Imperial

Meta Description: Tungsten carbide drawing nib blanks, developed with unique and consistent grades, manufactured to support fabrication of specialized designs.

Hyperion Code: WDSNR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication to DIN 1547.

Hyperion Code: WDINR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication to ISO 1684.

Hyperion Code: WDJNR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication to JIS G3521.

Hyperion Code: WDSNR

Dimensions: Metric

Description: Tungsten carbide drawing nibs (blanks) manufactured to support fabrication of drawing dies with an exit diameter between 12 and 61 mm.

Hyperion Code: WDRNR

Dimensions: Imperial

Meta Description: Tungsten carbide drawing nib blanks, developed with unique and consistent grades, manufactured to support fabrication of specialized designs.

Carbide Nib Blanks Applications

Cemented carbide nib blanks are a versatile tool used in various industrial applications requiring high wear resistance, hardness, and toughness. The commonly drawn wires using carbide nibs include steel wires, copper wires, aluminum wires, and other metals.

The drawing process produces wires of various diameters for various applications, such as electrical wiring, cables, springs, and fasteners. During the wire drawing process, the wire is pulled through a series of dies with decreasing hole sizes, and carbide nibs are used as a part of the drawing dies to reduce the diameter of the wire. The carbide nibs come into direct contact with the wire and must withstand the process's high pressure and wear.

Carbide Nib Blanks Products

Carbide nib blanks are known for their impeccable geometry and unique and consistent grade composition. We offer a huge range of standard dimensions and a superior quality of special designs: DIN, ISO, JIS, and Large. These nib blanks are manufactured in cemented carbide and are best suited for wire drawing soft and hard-metal dies.

Frequently Asked Questions about Carbide Nib Blanks

Carbide nibs are raw materials manufactured from tungsten carbide mixed with a metallic binder, such as cobalt, to withstand high pressure and wear to reduce the diameter of wires. It is commonly found in drawing steel, copper, aluminum, and other metal wires.

Carbide nibs are used to produce wire drawing nibs for the wire drawing industry. They are used as a part of drawing dies and come into direct contact with the wire as it passes through the die. The nibs are designed to withstand the high pressure and wear of the wire drawing process while maintaining their shape and size over time.

Carbide nibs offer many benefits and advantages over other materials used to make wire drawing nibs, such as longer tool life, improved wire surface finish, and reduced downtime. They can also draw a wide range of metals, including steel, copper, and aluminum.

Choosing the right carbide nib blanks depends on several factors, such as the type of metal being drawn, the desired wire diameter, and the specific requirements of the wire drawing process. Consulting with a knowledgeable supplier can help you select the right carbide nib blanks for your application.

Carbide nib blanks are available in different grades and sizes to meet the specific needs of different wire drawing applications. In addition, they can be customized to meet individual customers' unique requirements. At Hyperion Materials & Technologies, we provide several different product families of carbide nibs from DIN, JIS, ISO, and Large.